Machines are useful and efficient helps that make working easier and more productive. The better they are controlled the better they will perform. The same is the case with generators. They are also efficient alternatives to power in case of emergency or when the power grid disconnects. Just like any other complex machinery, generators also require a user interface that allows the users to monitor all its functions, check if everything is operating properly, or intervene as required. Machines often face several issues that impact their performance. From overheating, slowing down, and speeding up to malfunction due to different reasons like fatigue, weather conditions, or general wear and tear, machines require controls to ensure that they continue delivering the results they are expected to.

In electric machines like generators, the varying changes constitu te an electrical circuit that can be smartly processed in order to control the performance. In today’s technologically advanced world, several machines come with the option of automatic controls like sensors. These sensors smartly detect and sometimes even predict changes in variables and control the machine’s performance. The same is the case with generators. Advanced mechanisms and control panels allow generators to deliver better results without having to invest a lot of time and effort or human intervention.

It is clear that control panels are important components of machines and they must be understood well to utilize them properly and ensure that your productivity remains at its best. In this article, we will tell you everything about the control panel and how they are used.

What is Control Panel?

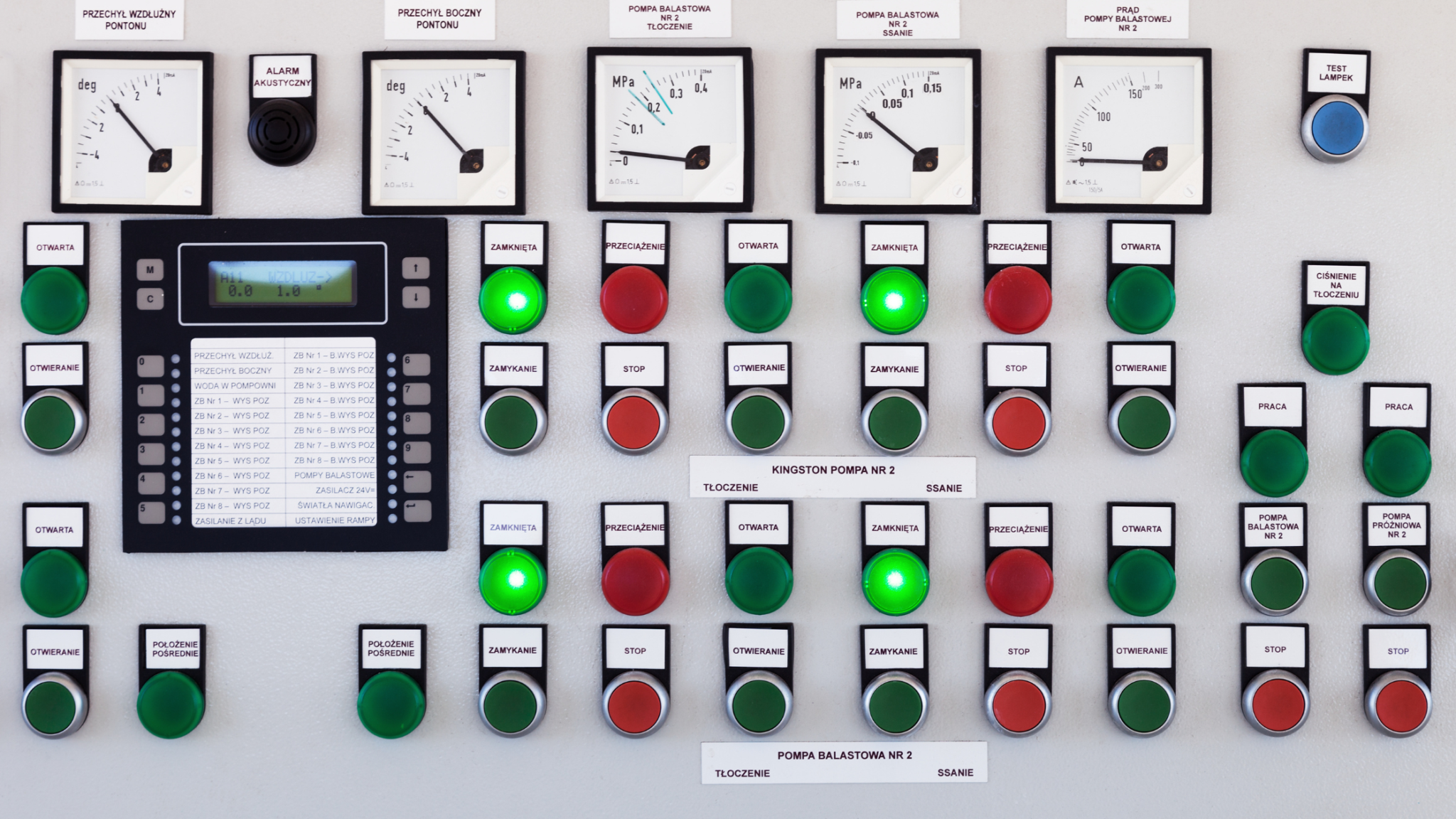

Control Panel is a visual presentation of various parameters like voltage, current, and frequency, through gauges and meters. These meters and gauges are enclosed in a case made of metal. These metal boxes are usually corrosion free so that the control panel can be protected from rain, snow, and other weather conditions.

In small generators, the control panels are built-in into the generator’s body itself. If this is indeed the case, they are provided with a vibration-free mechanism to isolate them from electric shock. Control panels of larger, industrial generators are mostly separately installed and they are also big enough to stand on their own. They could be designed mounted on a shelf or a wall and installed in an enclosure. Moreover, they are often accompanied by an Automatic Transfer Switch Panel or ATS Panel.

All control panels in modern generators come fitted with buttons and switches like switch on and switch off buttons that control the generator as needed. These switches are grouped together according to their functionality ensuring a well-defined display parameter. This is done to make the control panel more user-friendly so that the generator operator doesn’t press the wrong control by accident, as it can lead the generator to perform unwanted actions.

How Control Panels Work?

Control Panels have evolved over a period of time. From being manually operated to being sensor-enabled operations, they are now capable of sending automated inputs and giving feedback to the machine, and managing their operation on their own. Some of these automated responses could be regarding the temperature of the machines (in case of the machines overheating), over or under-speeding of the machine, or high or low oil pressure. In fact, the sensors can now even manipulate input to facilitate a common feedback setting, such that

These automated responses help operators manage the machine better. In the above-mentioned examples, the sensors inside the generator would sense any change in the programming of the machine and run system diagnostics, and pass the message to the microprocessor. The microprocessor, in turn, instructs the control panel to make the necessary changes.

This kind of functioning of the control panel is increasingly becoming critical in industrial setups where machines, especially generators are an important part of the operations as they provide the much-needed power supply in case of the power grid going off or any other emergency situation. Certain control panels come combined with an Automatic Transfer Switch to maintain a continuous supply of power. The ATS detects a power outage of the grid and signals the control panel to switch on the generator.

The signals that a control panel sends are determined by the kind of generator being used and the kind of power requirement of the set-up. Once the generator starts and reaches its optimum speed, the starter disengages. The ATS automatically switches to the power being supplied by the generator and you can continue functioning as usual without having to scramble around to fix the power outage. This automated functioning of the control panel makes it extremely important at homes and industrial setups during emergencies.

Custom Control Panels

While most control panels provide generic things like nonstop digital readouts, oil pressure and water temperature sensors, wiring harnesses, large character LCD screens, remote and local start/stop proficiencies, displays with running time, set points, and custom message options, and shut-down capabilities, you can opt for custom control panels as well. This could include specially designed meters and gauges, specific parameter readers, customized LCD indicators, different automation operatives, etc. If you have different needs than what a regular control panel provides, you can have custom control panels specially designed and fitted into your system that will fulfill your unique requirements. Custom control panels are increasingly becoming more popular in industrial applications as they make things more controlled.

Control panels are important elements of a generator. They allow proper and controlled operations of the generator engine when in dire need. They can be customized as well to suit the unique requirements of the application to give a more efficient output. So, next time you look to purchase a control panel, buy one that fulfills all your requirements for the best results.

If you still have any doubts or questions regarding generator control panels, or simply want to know more about our collection of new and used generators, please feel free to get in touch with us!

Frequently Asked Questions About Control panel in Generators

Where can you find the control panel of the generator?

The panel may be set up on the body of the generator itself, which is usually the case with small generators. If they are mounted on the generator, they typically have vibration proof pads that help isolate the control panel from shocks.

What are the most common parameter monitors on the control panels of generators?

Common parameters you may want to measure are the oil pressure, oil level, water temperature, engine speed, runtime, fuel flow and output. Many generators give access to a lot more data than this if you require it.