A diesel generator is a perfect source of power in instances where electric power fails. During thunderstorms, it is not uncommon for different areas to experience standby power system failures which result in financial loss due to downtimes in commercial facilities. With the recently issued tornado watch for the larger part of Wisconsin, now is the perfect time to keep your generator in perfect working condition.

In this article, we discuss 7 reasons why you should not gamble about maintaining your portable generator, that can deliver adequate starting power for your backup power needs.

1. Preventative maintenance helps catch and repair generator problems as early as possible

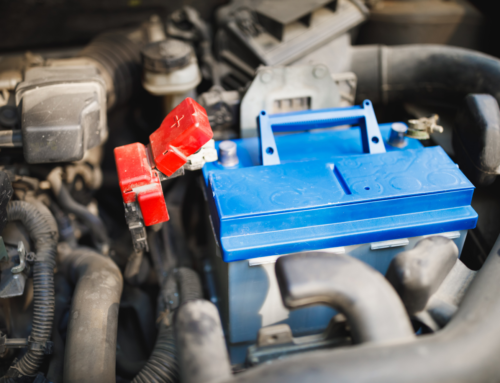

Although diesel generators are sturdy, durable, and quite reliable, making sure they undergo preventive maintenance is recommended. Plenty of generators will not immediately manifest symptoms of failure until the generator is unable to run when there is a power outage. Regular preventive maintenance enables the technician to identify problems with your standby generator, through both visual inspections as well as hands-on checking. This helps get hold of problems such as that with the manual battery load tester, internal combustion engine, DC electrical system and resolve them before they get any worse.

2. A well-defined maintenance schedule ensures proper functionality

During routine engine exercise, in addition to visual inspection of the portable generator, the technician ensures to –

- Change the engine oil

- Replace the generator’s air filter

- Check for loose connections

- Ensure balanced coolant mixture, and introduce coolant additives if needed

- Check if the generator supply connections

- Inspect the belts, hoses, lines, connectors, and any other accessories

- Check the control panel as well as the engine

- Clean the exhaust system if the dirt appears excessive

Regularly checking all these aspects ensures that your generator performs optimally at all times.

3. Generator maintenance prevents carbon monoxide generation and poisoning

A generator that is not regularly maintained is prone to producing carbon monoxide, which is fatal if it is inhaled. During the maintenance process, the technician will ensure that the generator is positioned in such a way that it releases any fumes outdoors rather than indoors.

4. Maintenance tips help increase your generator’s efficiency

Wasps, birds, rats, snakes, and other critters can infest your generator’s housing. Rats and mice are especially notorious for setting up a nest and chewing through the appliance’s wiring. During maintenance, all the parts of your generator such as air filters, air intake system, oil filter, spark plugs, cooling system, battery cables, are checked and cleaned from potentially damaging dirt and debris. They are then tested to ascertain that they are working as intended. These steps are essential for maintaining the quality and performance of The Best Industrial Generators.

5. Generator maintenance checklist helps prevent fuel tank and fuel filters problems

Generators running on diesel need to have the fuel tank cleaned, and the fuel supply changed at least twice every year. This is because the fuel deteriorates with time, especially when the generator goes for long periods without being operated. Regular maintenance ensures that the fuel system functions flawlessly. When you change fuel filters on time and drain the fuel system as required, the generator can function more efficiently, and the fuel consumption can be maintained at an optimal level.

6. Preventative maintenance tips ultimately saves you money

Ignoring regular generator maintenance might save you a few bucks today. However, this could lead to costly repairs. In extreme cases, you may have to replace the entire unit.

7. Preventative maintenance prolongs the generator’s lifespan

Unmaintained generators normally have shorter lifespans. As you do not want to constantly be on the lookout for a diesel generator for sale, it only makes sense to take care of your investment. Keeping the generator properly maintained ensures that it runs smoothly for longer.

If you are looking into investing in a generator for your industrial or commerce al facility, Central States Diesel Generators has a solution for you. Apart from stocking different types of generators for sale, we have the necessary knowledge and experience when it comes to maintaining your generator.

Frequently Asked Questions Regarding Maintenance of Heavy-Duty Diesel Engines Generators

How often should I service my portable generator?

A vast majority of new standby generators require their engine oil to be changed after 30 hours of use. Post this, change the oil after every 100-hour use. Of course, it is best to go through the engine manufacturer’s recommendations to ensure the best preventative maintenance including timely fuel filter changes as well as to keep engine parts lubricated.

How long should I run my diesel generator for maintenance?

To ensure the best preventive maintenance of your standby generator, we recommend running the generator set at full capacity for at least 25-20 minutes every week. Not only will it help the stored fuel heat up, but will also enable the lubricating oil to circulate within the engine. This small yet significant engine exercise will keep your portable generators in the best possible shape for a long time to come.

![How to Leverage Remote Monitoring for Your Industrial Generator?[2024 guide]](https://csdieselgenerators.com/wp-content/uploads/2024/03/Remote-Monitoring-500x383.png)