Wondering how you can leverage remote monitoring for your industrial generator?

Power supply intervention is out of the question for industries, especially hospitals or transportation. Depending on the industry, the requirement for a reliable industrial generator increases to keep the power on and let the operation continue without any hassle.

But the challenge is what you will do if your generator dies at a very crucial time. And it can be a highly possible situation; maybe it’s a small issue that led to overheating. But how will you know when to fix your generator or have an up-to-date overview?

This is where Remote monitoring comes in. But what is remote monitoring, how does it help, and what can take the best out of it?

To help you with that, here is what you should know.

What Is Remote Monitoring?

Remote monitoring is a smart way to control and oversee the generator as well as its equipment performance.

To understand it better, let’s know more about the key components of the remote monitoring system.

The system works to gather all the data straight from the generator’s engine. After the collection, it gets transmitted to the remote getaway, and to do that, here are three common practices that have been used for gathering the data.

ECM With Advanced Control Panel Generator

Since the 1990s, the new generators have utilised their digital control panels. These have the interface directly with ECM to control the generator operation. The system gathers the information and connects to the control panel through MODBUS or MODLON.

ECM Controlled Generator

ECM or Engine Control Module is a set that incorporates the generator modules related to control into the single operating system.

This configuration allows for advanced parameter monitoring via a remote monitoring getaway. Generally, the system connects the generator through a MODBUS or MODLON connection.

Non-ECM Controlled Generator

Generous sets before the 1990s didn’t have modern ECMs for controlling operations. Instead, the system depended on the analogue controls and the gauges.

Due to this, it was limited to analogue signals, converting the digital signal through an A-to-D converter. They did have monitoring for the basic generator parameters, but a speciality wiring harness was required for the job.

Data Transmission To the Gateway

Once the system gathers all the information, it transmits it to the processing software or the database. To do that, several methods are used, such as :

- Cellular IOT connection

- Satellite IOT connection

- Hardwired connection

- Remote Annunciator Panel

User Remote Access To The Generator

After the data gets transmitted to the remote software, you can interact with this information differently. Through the applications like cloud or onsite to process the data and make it accessible.

How To Leverage Remote Monitoring For Generators?

To understand how to leverage the remote monitoring, let’s understand common generator failures. It includes :

- Failure in the battery charger

- Failure in Block heater

- Low batteries

- Low fuel supply

- Automatic transfer switch issue

- Shut down alarms due to leaks, low coolant levels and more

- Block feature failure

Benefits Of Remote Monitoring

Now you know the common generator failures, here is how remote generator monitoring helps and improves the facilities management; it includes :

Minimizing The Downtime

Remote monitoring helps in keeping the gun sets in working order. It helps in reducing the incidents that lead to failure during the power cuts.

Not only does it ensure your generator supplies the backup when needed the most, but it also minimizes the downtime for the operations.

Get The Updates On Real Time

Another benefit is getting access to your generators regardless of where you are. It takes less than 5 seconds!

Reducing Expenses on Operation

Remote monitoring proactively addresses all the issues in the generator. It helps in getting an early diagnosis and helps in avoiding any kind of problem that can lead to bigger issues. Not only do these issues cost you time, but they also can increase your expenses!

Track the Location

The controller sometimes offers the built-in, or you can add it, but GPS tracking lets you easily know where your agent is. It gives you easy access to the fields where they might be delayed.

Steps To Setup Remote Monitoring For Your Generators

By now, you are fully equipped with all the basics; here are a few steps to set up your remote monitoring of the generator.

Step 1: Clear You Basics

Before you decide to set up, make sure you are aware of the monitoring process and familiar with the basic terms, such as :

RS-485

Its standard defines the electrical characteristics described as well as drivers that are in use of serial communication systems. It’s relevant for monitoring as it’s the most common way to leave a message through MODBUS.

MODBUS Protocol

MODBUS is a communication protocol for connecting the supervisory computer with an RTU or remote terminal unit. It’s in supervisory control and connects with SCADA or a data acquisition system.

0-5 VDC or 4-20 mA Sensors

These sensors are traditional analogues that help measure the variables, including fuel level, pressure, and temperature. It converts this variable into voltage or current signals. Also, to measure, general-purpose analogue inputs to RTU are needed.

Step 2: Setting Up Your Monitoring Sensors

Besides knowing the basic terms, the next step you need to follow is setting up the monitoring of sensors. It includes :

Fuel Level

Installing the fuel level sensors in the generator’s tank works to monitor the fuel level continuously.

Also, these are analogue-type sensors, providing the output of 0-5 VDC or 4- 20 mA respecting the generator’s tank.

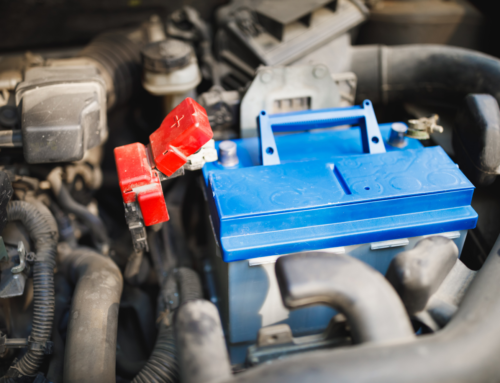

Battery Voltage Sensors

Other sensors are installed to monitor the operational status of the generator for monitoring the battery voltage. Through this, you can ensure the battery is in good condition or requires change.

Temperature And Pressure Sensors

These sensors help in deducing the condition of the generator, so if there are any issues related to running or faulty, you know it on time. Also, it shows the indication of overheating or pressure build, which are some of the reasons that severely damage your generator.

Step 3: Establishing The Data Collection

After you set up the sensors, the next step in your remote monitoring is to collect the data provided. Using a SCADA system or any similar data acquisition can do the job.

Such a system helps collect all the output signals they receive from sensors and convert them into meaningful data.

To secure the connection, you can use the RS-485 communication standard along with the MODBUS protocol. This will make your data transmission reliable and secure over distances, which is especially suitable for remote locations.

Step 4: Interpretation of Data And Monitoring

Interpreting data in real-time for effective generator monitoring. A good system can help you interpret your data and provide meaningful insights.

Step 5: Routine Checks And Maintenance

Besides all the steps, you don’t want to have a faulty remote monitoring system, especially during peak times, do you

Make sure to do routine checkups and regular services like oil or filter changes, which are important to increase the reliability and longevity of your enterer.

Looking For A Fuel Efficient Generator For Your Company?

Remote monitoring gives you peace of mind. You stay updated and have access to the generator’s whereabouts. From getting the reporting on its functionality to any issue detected on time, it will let you focus on what’s important.

At Central State Diesel Generator, we provide the best deals on generators that are right for your business. From our wide range of options, including the biggest brands that suit your budget, we cover all for you.

Common Questions On Leverage Remote Monitoring

Can I control the generator remotely?

Yes, Remote monitoring allows you to control your unit regardless of where you are and whatever time you wish.

Does Generator have the tracking devices?

With the help of remote monitoring, you can use GPS trackers to solve the issue and get the exact location of your generators.

Why is remote monitoring needed?

Remote monitoring systems give real-time information about the generators besides the ability to audit, ensuring continuous operation and extending the life cycle.