Diesel generators are one of the most widely used and trusted sources of alternate power. Their durable nature, robust build, efficient performance and cost-effectiveness make them highly preferred power backup support systems across different kinds of industrial and commercial setups.

Be it high power demand or long working hours, diesel generators provide both with ease. This is the reason why diesel generators are rated so highly across the world. Yet, what makes them stand out is that they can start off the power on the full load within minutes without any lag.

This is a great performance incentive for setups that just can’t afford to lose power. Setups like manufacturing units, hospitals and other similar emergency service providers that depend on electricity for functioning rely on diesel generators to ensure that there is no lag when power from the grid switches over to generators.

While these are significant benefits that diesel generators provide, the best thing about them is that all these benefits come at fairly low maintenance. Due to their robust and reliable make, they don’t need to be maintained as carefully as some of the other generators do.

Their comparatively lower fuel cost and the capability to perform even in harsh weather conditions further enhance their performance quotient.

However, if you wish to maximize their performance and the benefits they provide, you must keep them in good running shape. Timely servicing and maintenance will not only lend powerful performance but will also ensure that your generator doesn’t conk off during an emergency.

Diesel generators too, just like any other machine, go through their share of wear and tear which must be balanced out with timely servicing and maintenance.

In this article, we will tell offer you a generator maintenance checklist, that will help you keep your diesel generator in the best running condition so that you can reap maximum benefits from them.

8 Tips for Service and Preventive Maintenance of Standby Generators

Timely, Routine Maintenance

If you want your diesel generator to perform well and have a long shelf life, timely and routine maintenance is a must.

As you continue using your diesel generator, its exhaust system, fuel system, DC electrical system and the engine must be monitored closely for any leaks or other kinds of malfunctioning. Moreover, the oil filter (aka fuel filter), air filter, spark plugs should also be inspected regularly.

This will not only let help you keep the portable generator in good running condition but will also help you detect any defect in advance so that there you don’t get any unpleasant surprises of the generator conking off during an emergency.

Besides, you can replace air filters, change fuel filters and take care of other such small yet important tasks, well in time. Routine servicing will ensure proper preventative maintenance.

Did You Know? Changing engine oil every 100 hours of use is a must. It will ensure the trouble-free, long-lasting life of the generator.

Lubrication Needs

It is important to keep the engine properly lubricated at all times. To ensure this, you must check the engine oil while shutting down the diesel generator at regular intervals. Use a dipstick to do so and allow let the oil in the upper portions of the engine to drain right back inside the crankcase.

Then, follow the manufacturer’s manual to understand the API oil classification and its viscosity. It is essential to keep the oil level as full as possible on the dipstick.

If you see any dip in the oil level, refill the tank with the same quality engine oil. Similarly, you must also change the filters at regular intervals. Follow the manufacturer’s manual to know how to drain and replace the oil. That apart, you must also read about disposing of the filters properly so that you don’t add to the environmental damage and liability.

Inspect the Cooling System

The cooling system of a diesel generator is an extremely important component that ensures smooth and interruption-free functioning. During the shutdown period, check the coolant level regularly.

Once the engine has been shut down and cooled, remove the radiator cap and refill the coolant level to ¾. Most diesel engines, especially heavy-duty ones, require a balanced coolant mixture of water, antifreeze, and additives. This should be maintained at all times for better performance.

Furthermore, check the exterior of the radiator and remove any dust or foreign materials accumulated on and around it with a soft brush so that there is no damage to the fins of the radiator. You can also use low-pressure compressed air or steam to clean it all.

Check the Fuel System

Diesel, as a fuel, is prone to contamination and corrosion within a period of one year. So, it is necessary to run the generator every now and then to protect the fuel from degrading.

This is especially needed if the generator is not being used on a regular basis. All fuel filters must be drained and cleaned at regular intervals as water vapors accumulate and condense on the fuel tank.

Regular testing and polishing of the fuel is also a good practice to ensure that it remains in the best form. It should be replaced in a time span of three to six months. Preventive maintenance should also include regular checking of starting system and charge-air cooler piping and hoses to ensure that there are no leaks, holes, dirt accumulation or cracks anywhere.

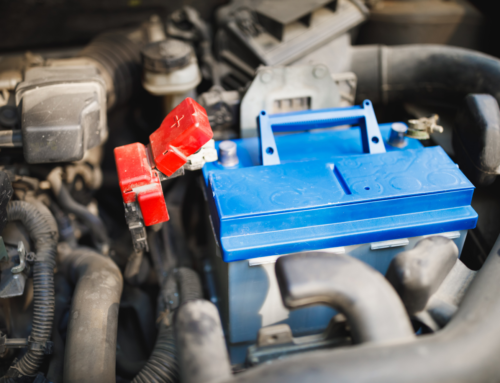

Test the Batteries

Unchanged or weak batteries are one of the common most reasons for generator failure. Batteries must be regularly checked and kept in full charge to ensure that they are working in the best condition.

This will avoid any starting trouble with the generator. They must be regularly cleaned and the gravity and electrolyte level must be maintained.

Batteries must also be regularly tested for their ability to work properly. As they age, their internal resistance to current flow increases. So, they should be regularly checked under load. While in some generators, this testing is done automatically when the generator starts, other generators require manual testing.

Additionally, batteries must be cleaned regularly of any dust accumulating on them. If you see corrosion developing on the terminals, remove the cables and clean them with a solution of baking soda and water. Ensure the solution doesn’t enter the batter cells. Once you are done cleaning the terminals, coat them with petroleum jelly.

Lastly, check specific gravity and electrolyte levels. A battery hydrometer must be used in open-cell batteries. The electrolyte levels must be checked every 2 hours. If the levels appear low, refill with distilled water.

Ensure Routine Engine Check-ups & Exercising

The engine is the most important component of the diesel generator. So, it is all the more important to keep it in the best condition. To ensure that the engine remains up and running, exercise it regularly.

This will keep the parts of the engine lubricated and thwart oxidation of electric connections, uses the fuel and stops it from deterioration, and enables reliable engine starting when you use the generator. It is recommended that you exercise the engine at least once every month for a minimum of 30 minutes, loaded to at least one-third of the nameplate rating.

Maintain Cleanliness

Keeping the generator clean and tidy is not only about cleaning the exterior but also means keeping it clean from the inside. Check the generator thoroughly at regular intervals.

Check if there are any oil drips, leaks, or damages and if the hoses and belts are in good condition. Regular check-ups will ensure that any damage is identified and rectified immediately. This will save you from spending on expensive repair work and keep the generator running for a long time.

See related: How much does a Cummins generators cost?

Monitor the Exhaust System

The exhaust system is again an important component in keeping the engine working efficiently. Inspect the exhaust system regularly and ensure that if any kinds of leaks or damages are identified in the connection points, gaskets or welds, then they are immediately repaired.

Diesel Generators are amazing tools to keep the power running, even when the power grid conks off or the weather is at its harshest.

If you run an industrial unit, a medical facility, a commercial business, or any other similar establishment where you cannot afford to have a no-power situation, having a diesel generator as a back-up power alternative is a must for you.

Their ability to run with efficiency at the most affordable cost makes them highly desirable and preferred across industries. However, they are machines that require proper servicing and maintenance to ensure they continue performing well.

Generators don’t usually get used on a daily basis. This means they would sit without working for days and weeks at end, requiring even more attention to their maintenance. So, preventive maintenance and servicing are essential to ensure that they perform when needed.

The above-mentioned best practices will ensure that every part of the generator is taken care of and work just as desired.

If you still have any doubts or questions regarding the maintenance and servicing needs of your generator or are looking forward to buying one or more new or used generators, please feel free to get in touch with us!

Frequently Asked Questions About Generator Maintenance

What is the purpose of routine maintenance to generator?

Like any mechanical device, maintenance is critical for ensuring that a diesel powered standby generator will start and run when needed. A well-planned maintenance program is essential to the operation of any power generation system. Because of the durability of diesel engines, most maintenance is preventive in nature.

Where should generator be stored?

A generator should always be stored in a dry, cool, and ventilated location that’s situated far from your living environment. It should also be reliable. For that, look to DuroMax. We offer dual fuel inverter generators, which are more fuel-efficient than standard portable generators.

How do you prevent maintenance on a generator?

You should also inspect and drain the fuel filter water trap, record water within the fuel tank, check hoses and connections, and wiring within the fuel system. Once per year, you should change the fuel filter, clean the vents, test piping/connections, and test fuel quality.